Tools Required:

- Computer

- Nord Communication Cable

- Serial to USB Adapter

Or

- Nord Handheld Controller and Cable (SK PAR-3H)

- Pry-bar or long flat screwdriver

- 3/4″ wrench

With Computer:

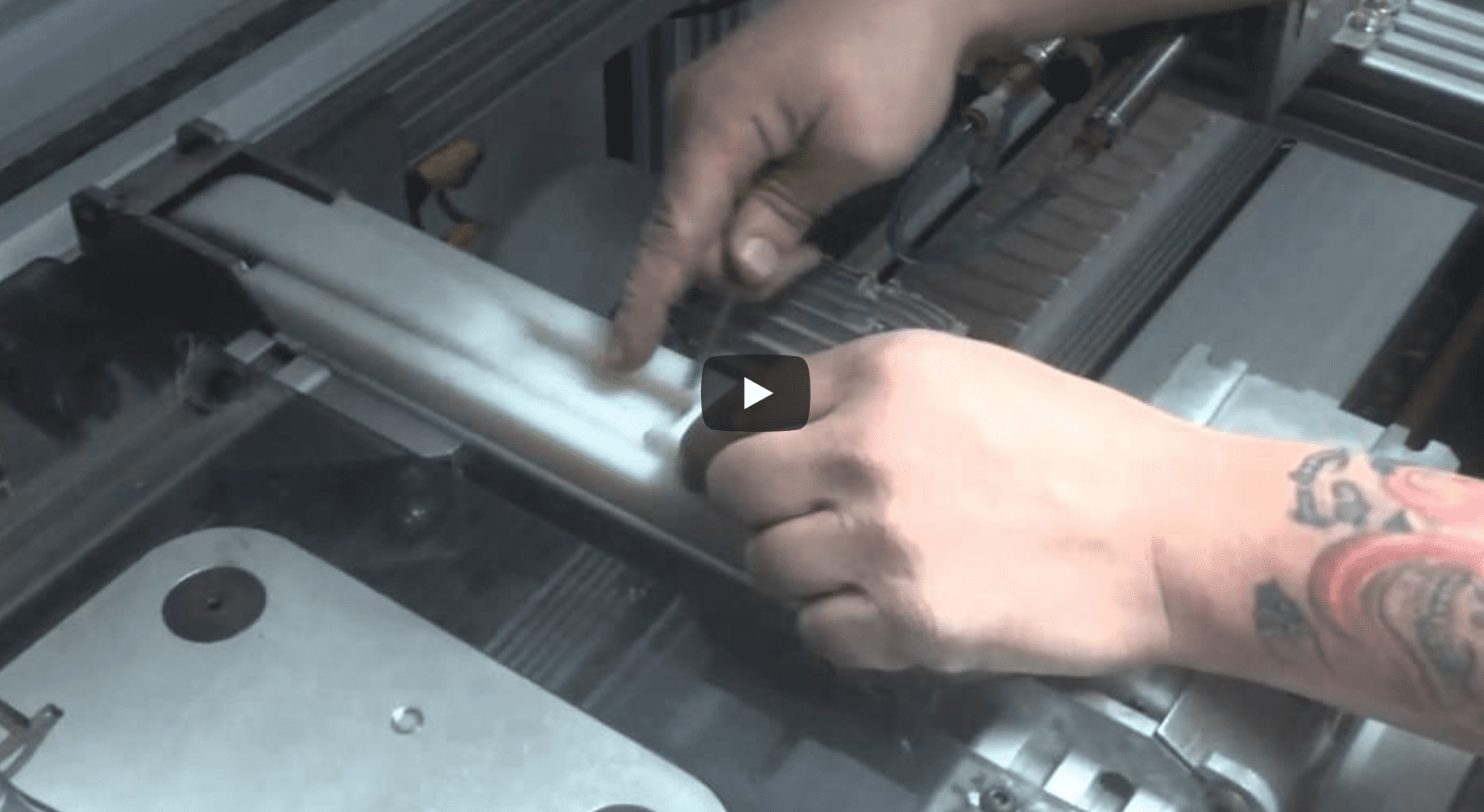

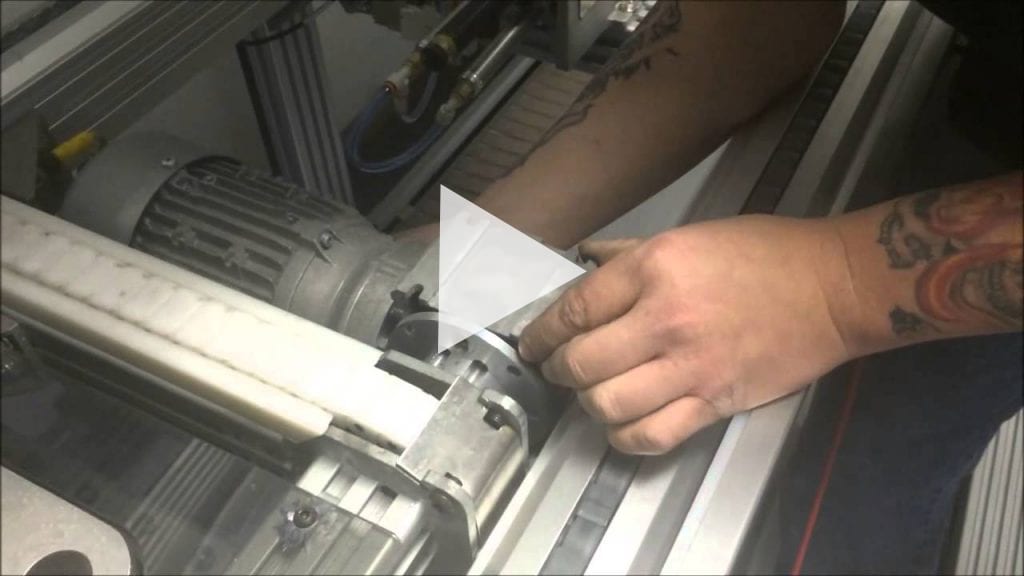

There are two types of control devices. One is a handheld controller and the other is a programming cable that you can hook up to your laptop computer. First, remove the cover over the programming access board. Plug one end of the cable into the VFD and plug the other end into your computer. Then, you need to figure out which communication port your computer will be using. To do this, go to the “Start” menu and go to “Computer.” Then, right-click and select “Properties.” Go to the device manager in the upper left corner, find communication ports down the list, expand it, and look for which communication port you’ll be using.

Remember which communication port it is, so we can set it in the software. Start the Nord Con software. Next, go to the “Extras” menu and select “Communication Settings.” In the dialog box below, select the correct communication port that you found earlier. Now, perform a “Bus Scan” from the menu above. The “Bus Scan” will find the appropriate motor that you’re connected to. Make sure that the motor “P1” says “Ready” and then select “Remote Control” from the dropdown above. From here, you can start and stop the motor, change the frequency, reverse directions, and change speeds.

With Handheld Motor:

The handheld controller works similarly to the computer. Simply plug in the same programming access port and you’ll see the device come on. From here you can control the unit – similar to the computer. First, go to “Parameterization” and then “Extra Functions.” From here, select “OK” and go to “Parameter 509.” Change to “USS” and, once again, select “OK.” Now, scroll to the left, until you find “Back.” Select “OK” and scroll left again until you find “Back.” Now select “OK” once more. Scroll left one more time and you’ll see the frequency that you’re currently running at. You can change this frequency with the up and down arrows, start and/or stop it, and even reverse the direction.